传 真: 021-62315435

邮 编: 200042

|

Thermal

Paint

Introduction

Thermal Paints are coating based products that are temperature sensitive. When

applied correctly, they create irreversible visual pictures of surface

temperature contour patterns. This is an essential tool for the accurate

analysis of high temperature materials working close to their maximum

temperature capabilities.

Thermal Paint Services, Inc. is a technical expert in this field

and has over 30 years of real world test experience with this product. The

company has invested many years of development in paint application

techniques, color contour analysis, incorporation of new technologies to help

in the data gathering and extrapolation and in the presentation and remote

management of test cells and data.

The performance of a gas turbine engine is significantly influenced by turbine

inlet temperature. Higher turbine inlet temperatures give high cycle efficiency

but at the cost of raising the component metal temperature. The allowable

component metal temperatures should not exceed 1700-1900 °F

(927-1038 °C) even for the most advanced alloy to avoid failures. Hence,

accurate measurement of metal temperatures of the components is essential for

component designers so that they can produce reliable and durable

engines.

A heat transfer engineer would have a wealth of useful data if a permanent

record of actual hardware temperatures in an operating gas turbine could be

made. However, measuring actual temperatures of rotating components such as

turbine blades using thermocouples through slip ring tests has been expensive

and difficult at best. In any case, only spot temperatures can be recorded.

Similarly, high frequency pyrometer techniques only give spot temperatures of

components on which a pyrometer probe can be aimed. Temperatures indicating

thermal paints offer a permanent, simple and relatively inexpensive way to

overcome this problem for both stationary and rotating components.

Although thermal paints have been used in turbomachinery design for a long

period of time, the results have often been discouraging due to subjective

interpretation of paint colors, sensitivity to the environment, and inaccuracy

of the predictions. Recent improvements in the application process, gas turbine

test procedure, and color interpretation technique have led to the solution of

these past problems.

Thermal Paint Uses and Advantages

The cost of a thermal paint test compared to a slip ring test is about

30%. By using thermal paints, the test and analysis time can be

reduced by a factor of 3 compared to a conventional test. This combination of

saving cost and test & analysis time reduces the development cost of a gas

turbine manufacturer many folds giving him an edge over competition. The other

obvious cost saving using thermal paints is that the painted parts can be

cleaned and reused after a test, whereas experience has shown that in a

conventional test with thermocouples, many very expensive Pt/Rh thermocouples

need to be attached to parts, and after a single test the parts are discarded.

Also, thermocouples can affect the aerodynamics and thermodynamics of the test

engine which is not the case with thermal paints.

After a test with the painted parts an overall coverage of

isotherms and temperature gradients over the entire surface of a component is

achieved and any local hot spot on a rotating or stationary part can be easily

identified. Any subsequent removal of the local hot spot can be visually

confirmed with thermal paints.

The paint color isotherms can be accurate to ±15ºF (±8 ºC) and

interpolation between isotherms can give an accurate assessment of the

temperature of any point on the component which has been paint tested. The

paints are being used with a high degree of accuracy and reliability in the

design and testing of combustion and turbine components.

The paints can be used on a variety of surfaces, including metallic, ceramic

and plastic, with applications in a range of areas such as:

- Temperature distribution on axial

flow compressor case exteriors, combustion

liners, combustion chamber casings - outer and inner, fuel injectors, glow

plugs, turbine stator vanes - all

stages, turbine rotor blades - all stages, turbine rotor wheels,

turbine vane cases and engine exhaust cones.

- Heat treatment processes

- Composite cure cycles

- Monitoring stored substances

- Monitoring furnace liner conditions

Paint Procedures

Thermal painting involves the applying of a very thin coat of a selected paint

to the required area of a component. Like the liquid crystals, the paint

changes to colors in response to specific temperatures. Unlike liquid crystals,

the reaction is irreversible and the paint retains the color corresponding to

the highest temperature it experienced, making it a permanent record.

The procedure is to paint the parts before an engine is assembled and then

simply install the painted parts into the engine during the test-stand build

up. (Painted parts can be stored in dry conditions for an indefinite period

without any resulting deterioration in performance). After the engine is run

for a predetermined period of time, the painted parts are removed and the

surface color contours remain as a record of the temperatures the surface

experienced.

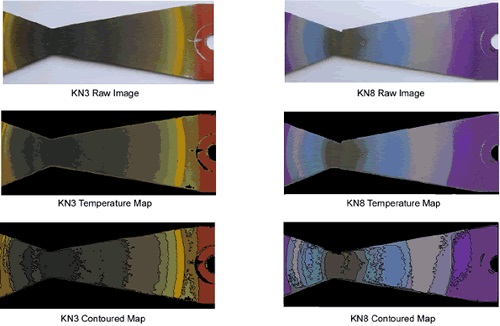

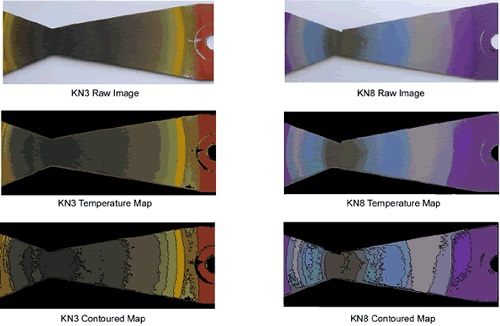

Interpreting Paint Contours

Skillful interpreting of the thermal paint coloration pattern

after a test run involves four major phases:

A. Isolating with boundary lines the various color zones on

the painted parts.

B. Assigning quantitative values to each isotherm area.

C. Recording the paint pattern, by photographic means.

D. Analysis by the engine designer.

The boundary lines of the paint color contours are sketched by

hand by skilled personnel. Alternatively, color digital photographs can be

taken and an image manipulating software can be utilized to process color

images of paint color contours.

Quantitative values are assigned to each isotherm area by the use

of calibrated test coupons. This is the key to the temperature/color

relationship.

Any single color in the series can span a 100-200 ºF (38-93ºC) temperature

range. So, assigning an exact quantity of temperature may seem a problem, but

an exact temperature can be assigned to any transition point between the

sequential colors. Also by using different paints with different color bands

(i.e. different temperature bands) for the same target surface temperature, it

is possible to narrow down an area's temperature to ±30 ˚F (±17ºC). For example: turbine rotor

blades which experience the same test temperature due to rotation can be

painted with different paints in order to narrow down the temperature

represented by the color bands.

The color change depends mainly on the operating temperature, but exposure time

to operating temperature also influence the color change. So the parts have to

be tested for selected times.

Analysis of the contoured parts by an engine designer often leads to

elimination of problem areas or to specific improvements in a previously

satisfactory component. Also several configurations of the same component (for

example different cooling schemes of a cooled turbine rotor blades) can be

paint tested in a single rainbow test to determine the resultant variations in

temperature due to different cooling schemes or the best feature of a

particular scheme. Cooling effectiveness can be calculated and the turbine

rotor entry temperature profile coming from a combustor can also be determined.

TPS Thermal Paints

Multi-Change Paints

|

Paint Name |

Temperature range |

|

|

oF |

oC |

|

|

KN1 |

320-446 |

160-230 |

|

KN2 |

468-491 |

242-255 |

|

KN3 |

914-2282 |

490-1250 |

|

KN4 |

219-405 |

104-207 |

|

KN5 |

307-1922 |

153-1050 |

|

KN6 |

302-2139 |

150-1170 |

|

KN7 |

662-1517 |

350-825 |

|

KN8 |

419-1670 |

215-910 |

|

KN9 |

215-910 |

232-262 |

|

KN10 |

752-1042 |

400-561 |

|

KN11 |

275-401 |

135-205 |

|

KN12 |

329-473 |

165-245 |

|

KN13 |

968-2021 |

520-1105 |

|

KN14 |

743-1076 |

395-580 |

|

KN15 |

531-2255 |

277-1235 |

|

Paint Name |

Color Change Temperature |

Initial Paint Color |

Final Color |

|

|

oF |

oC |

|||

|

CJKN1 |

118 |

48 |

Pink |

Lavender Blue |

|

CJKN2 |

176 |

80 |

Pink |

Lavender |

|

CJKN3 |

311 |

155 |

Blue |

Dark Green |

|

CJKN4* |

367 |

186 |

Yellow |

Black |

|

CJKN5* |

437 |

225 |

Yellow |

Black/Brown |

|

CJKN6 |

464 |

240 |

Yellow |

Red/Brown |

|

CJKN7 |

527 |

275 |

Blue/Grey |

Lavender |

|

CJKN8 |

693 |

367 |

Mauve/Red |

Grey |

|

CJKN9 |

752 |

400 |

Mauve |

White |

|

CJKN10 |

837 |

447 |

Green |

Salmon Pink |

|

CJKN11 |

856 |

458 |

Green |

White |

|

CJKN12 |

1022 |

550 |

Orange |

Yellow |

|

CJKN13 |

1166 |

630 |

Red |

White |

|

(* = Water based paints not suitable for spraying, should be brush applied) |

||||

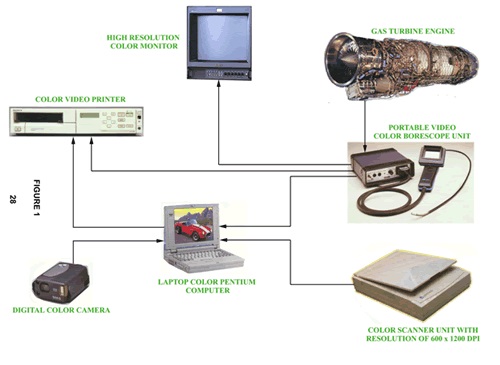

Thermal Paint Color Analysis Digital System (TPCADS)

The Thermal Paint Color Analysis Digital System (TPCADS) consists

of the following parts:

Hardware:

- Lumenera USB professional digital camera

- Lens and lens adapter

- Cameral adjustable rail

- Linear LED lights, with four 36w fluorescent tubes

- Kaiser Stand RSX with Arm RTX, base 20” x 24”

- Computer System with 19" monitor

- Another VGA display

- VGA splitter

- VGA extension cable

Software

Customized software for image acquisition and color

classification, incorporating the proprietary knowledge of thermal paint

pattern recognition and paint contours interpretation as well as many years of

experiences, following perfectly the procedure for thermal paint coloration

pattern interpretation procedure. Customers could store the color chip /

temperature data into the system for later color calibration, or make use

of the 3D color scheme, or even directly extract color from images as basis for

color recognition. Images will be processed automatically by the software in

order to output isotherms and temperature distributions. The software features

a higher capability of color recognition with more accuracy, and an absence of

human subjectivity of recognizing different colors, producing consistent color

results that can be repeated time and time again. Besides, all the results are

digitally stored, providing excellent support for interpreting personnel and

engine designers.

Schematics of TPCADS system, components and peripheral devices

Examples of the color analysis software