传 真: 021-62315435

邮 编: 200042

|

Blade Vibration Monitoring System

Hood Technology Corporation is a small, innovative engineering company located in Hood River, Oregon, USA, specializing in blade vibration & monitoring (BVM) for rotating machinery (e.g., gas turbine engines, turbochargers, steam turbines, compressors)

BVM refers to measurements made on rotating machinery using sensors that do not make contact with the rotor blades. A BVM system has a number of advantages over the traditional turbo-machinery measurement method (strain gages): data for each blade is acquired in a measured stage, and the instrumentation is non-contacting, which means that no slip rings or telemetry systems are required and the sensors can be replaced, if necessary, without dismantling the machine or even stopping the machine in some installations. Hood Technology has been designing and building blade tip timing systems since 1999 and has supported more than 200 tests on devices ranging from 5cm-diameter turbochargers to 4m-diameter steam turbines.

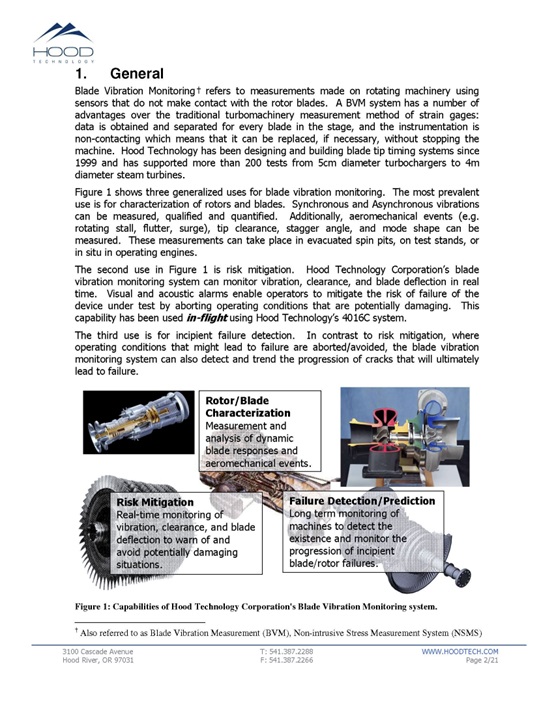

BVM is usefully applied in the following three areas:

Vibration Characterization

Hood Technology’s BVM can compare the actual performance of turbine blades with those predicted by theory, addressing extraordinary conditions such as extreme surges that are not adequately addressed by theoretical models.

Risk Mitigation

Unique to Hood Technology’s BVM is the ability to monitor blade vibration in a jet aircraft (either manned or unmanned) while in flight. Risk mitigation is used to avoid flight conditions that could lead to premature engine failure, thereby risking aircraft and personnel loss.

Failure Prediction

Hood Technology’s BVM offers turbine operators the unique ability to interpret data predicting incipient failure of turbine blades, which could lead to catastrophic failure of the turbine stage and extensive damage to the turbine.