传 真: 021-62315435

邮 编: 200042

|

ST ROBOTICS

Our aim in this deliberately simple website is to provide you with as much information as possible about our robots: specifications, diagrams, pictures, video, useful information, even prices. We invite you to discuss your application with us at your convenience.

Our aim in this deliberately simple website is to provide you with as much information as possible about our robots: specifications, diagrams, pictures, video, useful information, even prices. We invite you to discuss your application with us at your convenience.

ST aims to provide robots that are affordable, easy to set up and use and easily programmed by any individual regardless of experience. We provide free and unlimited support throughout the learning curve. We equally aim to provide a low cost solution to experienced users for a diverse range of advanced or complex tasks. Some users manage with our acclaimed manuals, some need more support and advice. It's what we do.

|

|

robotics within reach ** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Click one of the links below or click a picture for more information. |

|

|

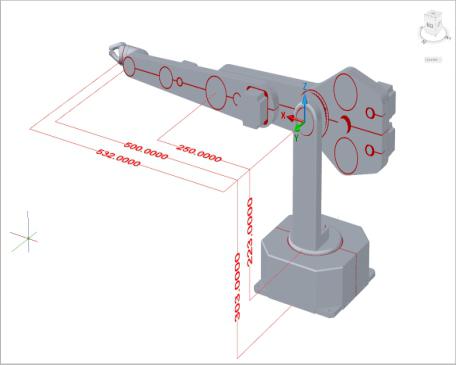

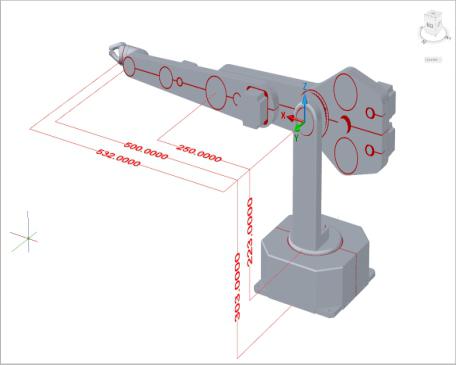

r12 robot arm

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

r17 robot arm |

||||||||

|

|

|||||||||

|

|

|

|

|||||||

|

|

|||||||||

|

|

|

|

|||||||

|

|

|||||||||

|

|

|

|

|||||||

|

|

r19 laboratory robot |

||||||||

|

|

|||||||||

|

|

|

|

|||||||

|

|

cartesian robots |

||||||||

|

|

|||||||||

|

|

|

|

|||||||

|

|

|||||||||

|

|

|

|

|||||||

|

|

confidence |

||||||||

|

|

|

|

|||||||

|

|

|

|

|||||||

|

|

|

|

|||||||

|

|

|

|

|||||||

|

Electric fulcrum gripper for R12 - E1

|

|

Electric fulcrum gripper for R12 - E2

|

![]()

|

Electric parallel gripper for R12 - EG12

|

![]()

|

Pneumatic grippers for R12 and R17

|

![]()

![]()

|

Electric gripper for R17 - EG17

|

![]()

|

Vacuum pickup

|

![]()

![]()

|

Tool changer system for R17 - TC17

|

![]()

|

Tool changer system for R12 - TC12 NEW

|

ST robots are not educational robots and we never expected to sell them as such. nevertheless a substantial number of our robot arms have been purchased by universities and colleges all over the world, particularly in the USA, and often re-ordered. Why is this?

Transparency

ST robots are not designed for transparency. It is a fact that a student may not learn from our robots about dynamics, PID feedback, kinematics. It's all done for you. However the majority of students will never get to design robots in the real world. It's much more likely they will be using robots. Students need to learn how to apply and program robots for real world tasks. It is analogous to computers - while some may be interested in how they work, the real world requires that they know how to use them.

Real World

Students need to learn how to solve real world appplications that they will find in industry and research. Industrial users are not interested in the inner workings; they want to get a job done. Our software does not waste time with offline programming, feedback loops, multi-axis kinematics that are of little use on the factory floor. ST software provides tools such as Cartesian coordinates, pose teaching and editing, continuous path control, palletising (matrices), I/O interfacing, interrupts, timing.

More importantly ST software uniquely gets the student up and running fast. Control of the robot is immediate and intuitive. There is an immediate response to everything the student does - no lengthy preparation or programming before anything even moves.

"We just finished the first course using the robot and everything worked great!

Students liked the robot a lot and found the programming interface easy to use and very intuitive."

- Indiana Tech.

"This thing is awesome! Loving it (and I know the students will as well). Great addition to our program.

16 second video clip attached (was amazed at how easy it was to get program wrote for it)."

- Halifax CC, NC.

Even though getting started with an ST robot is fast and easy there are a lot of things you can do. This means there is a lot of software. You may need only a fraction of it but it's all there if you need it.

Students can also write supervisors that send commands to the robot. We support ActiveX, LabView and Matlab.

Students in the past have also used C and Python.

Want to see what students have accomplished using our robots? Please see some of their work in these videos, also the University of Iowa , Florida Institute of Technology.

ST has a specially written course if required (see below). It is a spiral bound landscape format book with 45 pages. Each student gets his/her own copy. There are free copies with each (educational) robot and extra copies cost very little.

There is also a complete and thorough tutorial for advanced users.

David Sands on robot maths

ST has designed a kit based on Meccano/Erector-set that schools can use to teach basic robotics. It is a complete kit comprising 3D CAD software, parts, servos, an ARM based controller and a mini version of RoboForth. See

|

|

The laboratory workhorse For most laboratory applications we recommend the new R19. This may be mounted on a track which can be up to five meters long. New advanced drives ensure swift smooth motion and quiet operation in the lab environment. DSP technology provides fast multi-axis compound motion plus the ability to multi-task. The R14 is a mini-Cartesian robot suitable for positioning plates under fixed positions and similar applications such as the cool storage cabinet below. ST robots have the benefit of the ROBOFORTH II programming system which is more versatile by far than any competitive system. It is text based because it uses language; graphical simulations never simulate everything you might want to do. Once you have programmed the robot it may be supervised by any computer using your own software or proprietory supervisors such as Overlordand LabVIEW via the free ActiveX modules provided. The ST robot controller will also control other devices or take measurements from such as thermometers, pressure gauges, scales etc. and schedule and collect data using spreadsheet compatible files or upload to LabVIEW. |

|

Note: Most of the pictures on this page feature the discontinued R16 cylindrical format robot but we now supply the new R19. Many are mounted on a track which can be up to 5 meters long.

|

High-throughput expression and purification of membrane proteins

EBR: Robotics in Pharmaceutical Research by David Sands

A Fully Integrated Robotic System for High Sample Throughput Within a DNA Databasing Unit

(note: The ST R16 robot is mistakenly referred to as a Hamilton ML16 robot and Roboforth is also an ST product.)

The Scientist: High Throughput Thermocyclers

|

Robotics in the nuclear industry |

|

|

|

Not to be confused with telerobotics in which the mechanical arm is remotely controlled by an operator using CCTV, ST robots are programmable and autonomous. They are especially suitable for routine operations such as testing, swabbing and routine handling of samples. Typical applications include routine measurements, handling radiochemicals and nuclear decomissioning. Systems are always designed and built using the customer's standards, drawing standards and documentation requirements e.g. quality plan. A mock-up of the application area is made and the system is tested in the mockup using a formal works test procedure. Installation is done by our own technicians meeting all customer's safety requirements and using installation method statement or customer's designated documentation format. Emerald Article: Robotics in the nuclear industry

This page is organised as a series of pictures of actual applications with descriptions alongside (pictures speak louder than words!) |

|

|

|

|

A twin-robot system for swabbing steel boxes for waste products. |

|

|

|

Another view of the same robot showing the waste container outside the door. |

|

|

|

On the same wall but higher is the second robot which takes swabs from a glovebox and passes it to the swabbing robot. Access is via a lead shield door which can be seen to the left of the 'posting' robot. The door is under the control of the robot controller as is another door on the outside. The swab is placed on a shuttle by the operator and pushed into a tube. The outer door closes, the inner door opens allowing access by the posting robot. ST designed the glovebox, doors, drives and shuttle. |

|

|

|

Close-up of the exchange of swab from a posting robot to a swabbing robot |

|

|

|

Close-up of the 'M-axis', telescopic linear axis developed specially for nuclear use, as it will fit in confined spaces. It has integral yaw axis and gripper. |

|

|

|

Two robot controllers in one cabinet together with all necessary relays, interlocks and power drives for shield doors. Behind may be seen the viewing window and a row of tongs; to the right of the viewing window is a control pendant. All robot functions are controlled from this pendant. |

|

|

|

Another twin robot system in a mockup |

|

|

|

Another robot controller on another installation. Glovebox is behind. |

|

|

|

This robot is designed only for handling samples. Samples are housed in lead chambers with sheild doors. The robot controller controls the doors as well as gripper and interlocks. |

|

|

Home

|

Videos

|

Grippers

|

More information

|

Contact

|

|

|

So easy to use - anyone can do it.

You'll want to know that you will be able to program the robot for the application you have in mind. |

|

|

|

Alternatively you can use our simple free teach pad (left) to position the robot before learning the positions, or our Android bluetooth touch-screen teach console (right). See how easy it is: How-to videos |

|

|

|

Frequently asked questions:

|

In normal robotics the object must be in a known position - a holder or feeder or gate etc. ST Robotics offer a low cost vision system for determining the position of an object which is not in a repeatable position in the usual way. The vision system sends coordinates to the robot so it can be gripped by the robot regardless of position.

It comprises a high spec camera, C-mount lens with zoom, focus and exposure control and LED lighting with Matrox GigE interface and drivers. We can choose whichever camera size and resolution is required for the working area required. The hardware and software are easily installed in your own PC. The system includes all cables, CAT6 cable and camera power supply, all ready to go.

The camera and lighting should be mounted by the user about half a metre above the work area. The workspace should be shielded from stray lighting such as sunlight or fluorescent tubes. The camera is then calibrated to a disc and a rectangle of known size.

This is a high accuracy system that can measure to 0.1mm.

How does it work?

The PC connects to the robot controller in the usual way via serial or USB. A second serial channel (or USB converter) connects to the robot controller second serial channel. So there are now 2 serial connections between the PC and the controller. This permits you to write your program in RobWin and test out communication with the camera as you go along.

Software is provided for the controller i.e. commands or words that you can use. The simplest command is just VISION. This then sends a command to the vision system. The camera takes measurements and sends back the position of the object in X and Y coordinates plus it's angle. The robot now knows exactly where the object is and its orientation and can pick it up rotating the wrist as necessary.

Results box

Shown with the RobWin command window inset.

![]()

Final coordinates displayed and also sent to the robot. The RobWin window shows the simple command VIS and the results back from the vision system. the leading 1 means successful measurement.

The blue cross is the camera center (0,0). The mauve cross is the centre of the object, shown in this example as 7.6mm on X and 6.2mm on Y from the camera center with the object tilted to 2.7 degrees. Note that the centre of the picture is not X=0,Y=0 of the robot. These are relative positions. The robot system therefore adds offsets to reach the exact position required.

This video shows a typical application. A backing sheet feeds along a conveyor. The robot picks up a box and must place it on the backing sheet central to within 1mm. The vision system tells the robot what the X-Y position and angle of the backing sheet. The robot adjusts the box accordingly and lowers onto the sheet. Four example show how even extreme angles are handled by the system.

Parameters screen showing measured size of the object and camera settings.

![]()

Camera mounted on robot

This is another way of using the camera. It is more versatile because the robot can position the camera anywhere in the workspace but must be carried everywhere the robot goes which might not be convenient.

The robot first takes a 'look' at the object and the camera grabs the coordinates and orientation of the object. The robot can then move to that exact place and pick up the object. ![]()

· Search in a defined window, ignores everything outside.

· Light or Dark background selection.

· Multiple components, sends the coordinates of the component nearest to X=0, Y=0 image origin.

· Component parameters with tolerances to ignore anything outside these values.

Example of multiple objects:

The red areas are objects with parameters outside tolerance values.

Example calibration disc in a defined window with measurments and camera settings:

Capturing object of interest ignoring extraneous objects:

All engineered systems follow a recognized pattern of failure known as the 'bathtub curve'

.

The timescale for this curve is typically 10-20 years for electronics and 1-5 years for mechanical systems depending on stresses and the purpose of the system. A car, for example, might be expected to show signs of wear after, say 60,000 miles which at an average of 30 mph is only 2000 hours or about 3 months of continuous use. A machine in a production environment might be expected to work 3 shifts a day for, say 2 years before showing signs of wear which would be about 12,000 hours.

In the early part of a system's life things often go wrong. This accounts for the high failure rate in the early history and it reduces rapidly as time passes. This period is often referred to as infant mortality. In almost every case such failures are a direct result of manufacturing defects, for example a poor connection or a screw not tight enough or a part incorrectly made or fitted. No-one is immune although the motor industry has it almost beat. In small scale production as in the production of robots the answer is to cycle the system for as long as possible before delivery. Any defective component will fail during this period and not after it is in use by the customer. ST robots are run day and night for a week before delivery, which is not much but the curve is very steep at this stage. There is still the possibility of infant mortality after delivery but this is very much reduced and is covered by the warranty period. Infant mortality post delivery is usually quantified as a percentage i.e. percentage of units delivered which will go wrong during the warranty period.

Next comes a period of steady but low rate of failure which is usually quantified by MTBF - mean time between failures. Quite often this phase overlaps with the infant mortality phase. During this period also are failures due to design weaknesses or software issues. For example if a robot or other instrument changes calibration the 'fix' is easy but it is nevertheless a failure. The MTBF of an ST robot is approximately 10,000 hours.

Finally things begin to wear out (senility). Failure rates begin to gradually increase. The system can continue to be used but will require frequent maintenance and replacement parts. ST robots are expected to work for about 30,000 hours continuous light duty use.

I am reminded of a (supposedly true) story about someone who took a new Rolls Royce across Europe. In the middle of nowhere the half-shaft broke and he called the factory. They sent an engineer with a replacement by helicopter. When he got back to UK he called the factory to enquire if there was any charge for the exceptional service and was told: 'Sir, Rolls Royce half shafts do not break'.

From Wikipedia:

· Accuracy – is how closely a robot can reach a commanded position. When the absolute position of the robot is measured and compared to the commanded position the error is a measure of accuracy. Accuracy can be improved with external sensing for example a vision system or Infra-Red. See robot calibration. Accuracy can vary with speed and position within the working envelope and with payload (see compliance).

· Repeatability - is how well the robot will return to a programmed position. This is not the same as accuracy. It may be that when told to go to a certain X-Y-Z position that it gets only to within 1 mm of that position. This would be its accuracy which may be improved by calibration. But if that position is taught into controller memory and each time it is sent there it returns to within 0.1mm of the taught position then the repeatability will be within 0.1mm.

Accuracy and repeatability are different measures. Repeatability is usually the most important criterion for a robot. ISO 9283 sets out a method whereby both accuracy and repeatability can be measured. Typically a robot is sent to a taught position a number of times and the error is measured at each return to the position after visiting 4 other positions. Repeatability is then quantified using the standard deviation of those samples in all three dimensions.

· ST Robotics uses a modified form of the ISO 9283 test with less motion between samples. Positions are taught that test X Y and Z dimensions. Each dimension is tested individually. The robot goes into position against an LVDT (electronic dial gauge) and readings are taken automatically by the controller via the analog I/O card.

· A standard test is conducted over a 24 hour period with a short test over 5 hour period. Within the test the position is measured by the LVDT 30 times at 1 minute intervals. The robot then calibrates and another 30 samples are taken over the half hour period. From the readings we get it can be seen that calibration itself introduces some variation or lack of repeatability. For applications requiring much higher repeatability we advise absolute calibration using what we call a nest. Instructions for doing this are in our manuals.

· This video shows one cycle of the test for the Y dimension on an R12. The gauge is at Y=350mm

· · Note that any error in pitch also contributes to the drift. The graph below shows the a typical result from the above test. Vertical axis is times 0.001mm. Most of the drift is attributable to a change in temperature. The robot should be allowed to warm up for 30 minutes before use for best repeatability. Even so total drift is less than 0.2mm which is quite respectable for a low cost robot. Given a constant temperature a repeatability of better than +/- 0.05mm could reasonably be expected.

Our unique technology using micro-stepped motors, encoders, DSP control and polyurethane drives is how we can make very low cost robots with real industrial performance and durability.

Strengths

· For equivalent performance stepping motors are cheaper

· Stepping motors are brushless motors so have longer lifetimes.

· Being digital motors they can be positioned accurately without hunting or overshoot.

· Drive modules are not linear amplifiers which means less heat sinks, higher efficiency, greater reliability.

· Drive modules are less expensive than linear amplifiers.

· No expensive servo control electronics are required since signals originate directly from the MPU.

· Software is fail-safe. The MPU issues stepping pulses. If the software fails to work or crashes the motors stop.

· Electronic drives are fail-safe. In case of drive amplifier failure the motors lock solid and will not run. When a servo drive fails the motor can still run, possibly at full speed.

· Speed control is accurate and repeatable (crystal controlled).

· Stepping motors will run extremely slowly if required.

· All ST robots have encoder feedback which is compared to software motor counts. In the event of any error which cannot be corrected the system will halt. Thus the integrity of the system is much higher.

· Stepping motors are low speed high torque devices so transmissions are shorter which means higher reliability, greater efficiency, less backlash and lower cost. It is precisely this characteristic that makes steppers ideal for robotics since most robot motions are short distance requiring high accelerations to achieve low cycle times.

Criticisms and our answers

· Power-to-weight ratio is lower than DC motors.

Our answer: Most robot motions are not long range high speed (and therefore high power) but typically comprise short distances stopping and starting. With high torque at low speeds they are ideal for robotics.

· Stepping motors are positional devices so cannot work with errors, For example will not slow down under excessive load but will stall. They cannot be used to exert a force independent of position.

Our answer: Robots are positional devices, designed to move into precise positions without error. In the event of a stall or collision the watchdog encoders report the error and stop the robot from further motion.

· At certain low speeds stepping motors can resonate resulting in loss of synchronism and stalling.

Our answer: Each stepping motor drive is individually microprocessor controlled and drives the motors pseudo-sinusoidally known as micro-stepping. Micro-code watches for resonance and automatically shifts the phase and current to compensate.

· Stepping motors make more noise.

Our answer: Silent drives run the motors in micro-stepping mode throughout the speed range as can be seen in the videos.

· Continuous path is notoriously difficult with stepping motors.

Our answer: DSP hardware and software shares time between motors and simultaneously ramps individual motors up or down as necessary. The system has the advantage of zero overshoot on corners - if the required change of direction cannot be achieved it is reported beforehand.